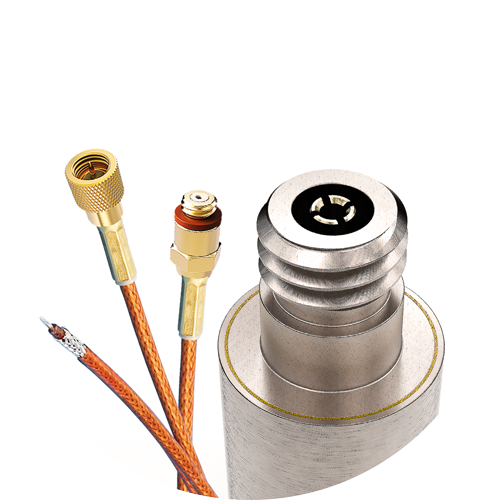

Microdot Coaxial Feedthroughs and Components

UHV Microdot Feedthroughs

The Microdot coaxial interface, developed for aerospace and instrumentation applications, is a small circular connector, which is sometimes mistaken for the slightly larger SMA coaxial connection. In its most common configuration, the S-50 series (the vacuum microdot feedthroughs offered on this site), it uses a No. 10-32 UNF (.190-32) thread. Male connectors are fitted with a 0.030/.033 diameter pin and jacks have the female mating socket receptacle. It is commonly used in conjunction with high-frequency, low noise, 50-Ohm instrumentation signal lines in accelerometers, and various transducer applications.

Microdot Feedthrough Construction

Accu-Glass Products' Microdot and "between-series" BNC-Microdot coaxial feedthroughs are constructed with grounded shields, where the feedthrough shield and flange are electrically common.

Microdot Feedthrough BNC-Microdot "between-series"

Microdot-BNC feedthroughs offer a simple means of transitioning between BNC and Microdot wired applications, or vise versa. The BNC-Microdot feedthrough is often used in conjunction with crystal sensors to monitor deposition thicknesses of in-vacuum coating applications. Microdot cable assemblies, connectors, and wiring accessories are also offered on this site. Rated for High Vacuum (HV) and Ultrahigh Vacuum (UHV) applications.

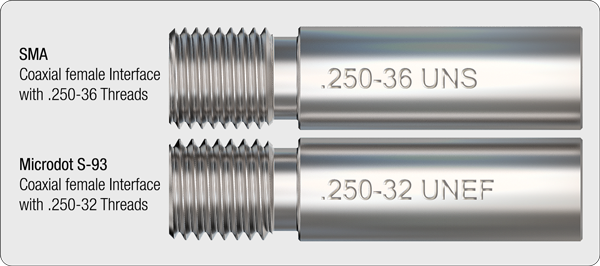

Warning — SMAs, with .250-36 thread and .035/.037 pin diameter, are often mistaken for Microdot S-93, connectors with .250-32 threads and .030/.033 pins. To avoid possible damage to one or both connector interfaces, these connectors should never be cross-mated. Compare Microdot ® and SMA differences below...

Features

- Microdot® and BNC Coaxial Interfaces

- Single and 'Between Series' Configurations

- Kapton® insulated, 50-Ohm cables

- High temperature rated to 250°C

- UHV compatible construction

- Conflat® and ISO KF compatible mounts

- Air service cables / connectors

- Custom solutions on request

Specifications

| Electrical | |

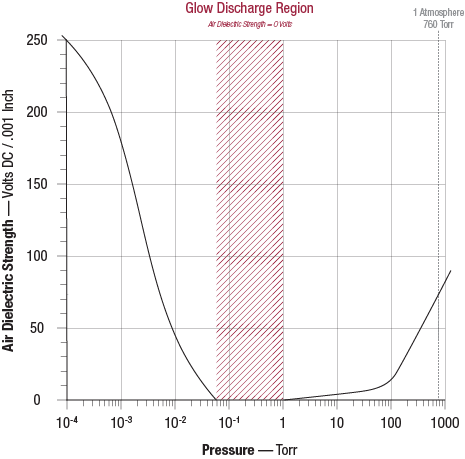

| Voltage 1, Maximum | 500 VDC |

| Current, Max @ 20°C | 2 A |

| Material | |

| Shell | 304 Ss |

| Pin, Ni-Plated | Ss / Mo |

| Insulation, Ceramic | Alumina |

| Connector, Vacuum 2 | |

| BNC, Ni-Plated | Brass / PEEK |

| Microdot, Au-Plated | Brass / PEEK |

| Cable Insulation | Kapton® |

| Connector, Air | Composite |

| Vacuum Range | |

| UHV, Ultrahigh vacuum | 1x10E-10 Torr |

| HV, High vacuum | 1x10E-8 Torr |

| Temperature Range3 | |

| Feedthrough, Single Ended | 250°C |

| Flange, Conflat® | 450°C |

| Flange, ISO | 150°C |

| Connector / Cable, Air | 165°C |

| Connector / Cable, UHV | 250°C |

| Thermal Gradient, Maximum | 25°C/minute |

| Notes |

- Electrical ratings are maximum test values, with feedthrough's vacuum side at ≤ 1x10-4 Torr. Feedthroughs are intended for instrumentation applications carrying low level signal voltage/current.

- PEEK is a polyether ether ketone thermoplastic.

- Overall assembly ratings must be adjusted to that of its lowest rated component. For cryogenic service, the lowest recommended temperature is -200°C