Subminiature-D Feedthroughs and Components

Subminiature-D or Sub-D

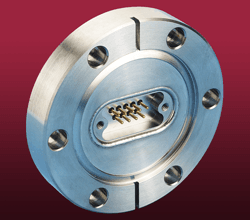

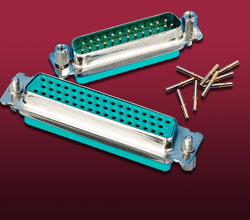

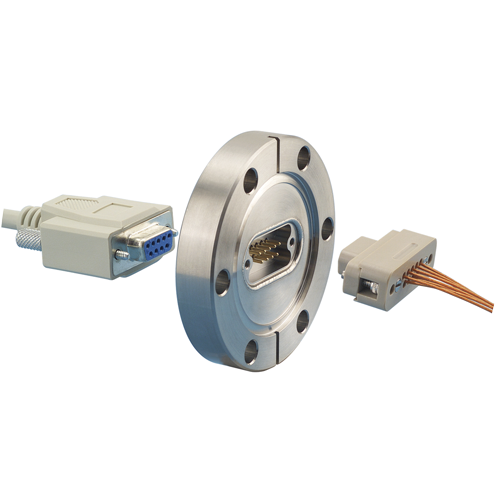

UHV 9, 15, 25, and 50-pin Subminiature-D (Sub-D) hermetic feedthroughs (vacuum feedthrough) are constructed with multi-pin arrangements per Mil-DTL-24308 (formerly Mil-C-24308) specification. All pins are gold-plated and arranged in a straight-through pin-to-pin design. Hermetically sealed and electrically insulated into a stainless steel shell using the latest in glass-ceramic bonding technology (ceramic feedthrough).

Multi-pin Sub-D Vacuum Feedthrough Connectors and Assemblies

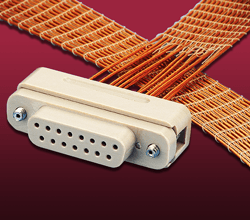

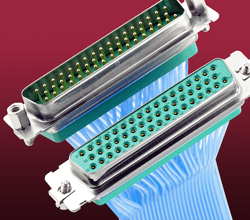

Ultrahigh vacuum compatible Sub-D wire assemblies are fitted with PEEK (polyether-etherketone) polymer connectors and Kapton® insulated ribbon cable to meet the rigorous demands of ultrahigh vacuum environments. Each subminiature-D vacuum connector includes two (2) captured stainless steel socket head screws that securely lock a connector to its mating electrical feedthrough. To eliminate virtual leaks, in-vacuum captured screws are vented where required.

Introducing the HV Bulkhead-D multi-pin feedthrough Product Line

AGP's HV Bulkhead-D hermetic electrical feedthrough was developed for high-vacuum flat-chamber-wall applications where conventional ISO NW KF or LF flanges are either not available, or just not practical. Our universal 2x3.5 inch rectangular flange, the Bulkhead-D flange, accommodates standard 9, 15, 25, or 50-pin subminiature-D electrical feedthroughs, and shares the same gasket and fastening accessories... providing simple and convenient interchangeability.

Features

- Subminiature-D 9 to 100 Pin configuration

- High temperature rated to 250°C

- UHV compatible construction

- Conflat® and ISO NW compatible mounts

- Kapton® insulated vacuum cables

- PEEK connector with locking screws

- Air-service cable assemblies

- Custom solutions on request

Specifications

| Electrical | |

| Voltage 1, Maximum | 500 VDC |

| Current 2, Maximum | 5 A |

| Material | |

| Shell, Stainless Steel | 304 |

| Pins, Au plated | Ni-Fe |

| Seal / Insulator | Glass-Ceramic |

| Connector, Air | Composite |

| Connector, UHV 3 | PEEK |

| Connector, HV 3 | DAP / Stainless |

| Vacuum Range 4 | |

| UHV, Ultrahigh vacuum | 1x10E-10 Torr |

| HV, High vacuum | 1x10E-8 Torr |

| Temperature Range 5 | |

| Feedthrough | -200 to 250°C |

| Flange, Conflat® | -200 to 450°C |

| Flange, ISO | 150°C |

| Connector / Cable, Air | 80°C |

| Connector / Cable, UHV PEEK | 250°C |

| Connector / Cable, HV, DAP | 125°C |

| Thermal Gradient, Maximum | 25°C/minute |

| Notes |

- Electrical ratings are maximum test values, with vacuum side at ≤ 1x10-4 Torr. Feedthroughs are intended for instrumentation applications carrying low level signal voltage and current.

- Per pin maximum @ 20°C. For proper heat dissipation, a maximum of 20% of pins on a feedthrough may carry the maximum pin current at any given time.

- PEEK is a polyether ether ketone thermoplastic. DAP is a glass-filled diallyl phthalate.

- Leak tested to 5x10-10 Standard cc/sec of He.

- Overall assembly ratings must be adjusted to that of its lowest rated component. For cryogenic service, the lowest recommended temperature is -200°C

- Unless designated a 'kit,' connectors and cable assemblies are not included with feedthrough and must be purchased separately.