Light Guide Feedthroughs

Light Guide Feedthroughs

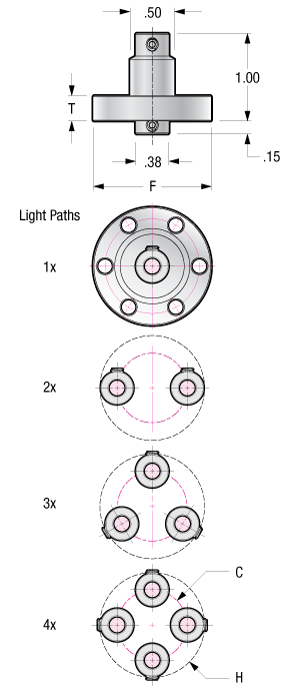

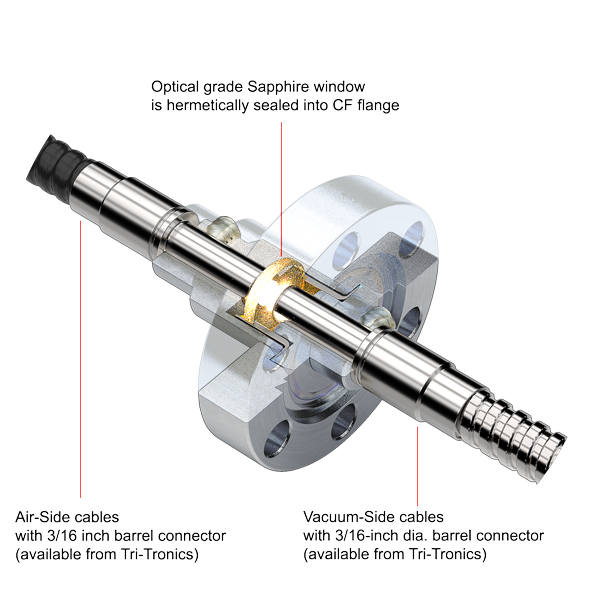

AGP Light Guide feedthroughs provide a simple and convenient means of introducing high intensity illumination into high and ultrahigh vacuum systems. Feedthroughs are offered in 1, 2, 3, or 4 light-guide configurations on Conflat compatible CF flanges. They are designed for use with standard flexible PVC and Stainless Steel bundled-fiber cables fitted with 3/16-Inch diameter (1/2-Inch long) barrel connectors. Each feedthrough path includes a hermetically sealed optical-grade UV grade sapphire window for maximum vacuum integrity and optimal light transmission. Air and vacuum-side feedthrough interfaces include set-screws to securely lock cable connectors in place.

Compatible fiber optic light-guide cables are available in various lengths and finishes from Tri-Tronix. Here are the corresponding links to the Tri-Tronix website... For Vacuum Service: High temperature fiber optic light-guide cables w/stainless steel jacket, .125 Glass fiber bundle, and .187 Barrel connectors. For Atmospheric Service: Standard temperature fiber optic light-guide cables with PVC Monocoil Jacket, .125 Glass fiber bundle, and .187 Barrel connectors.

Features

- UV Grade Sapphire Window

- Nickel-Iron alloy matched-expansion

- High temperature rated to 350°C

- UHV compatible materials

- Stainless steel and NiFe construction

- Conflat® compatible CF mounts

Specifications

| Material | |

| Flange | 304 Stainless Steel |

| Window 1, 2 | Sapphire |

| Vacuum Range 3 | |

| UHV, Ultrahigh Vacuum | 1x10E-10 Torr |

| HV, High Vacuum | 1x10E-8 Torr |

| Temperature Range 4 | |

| Seal, Sapphire-to-metal | 350°C |

| Flange, CF | 450°C |

| Flange, ISO NW | 150°C |

| Thermal Gradient | 20°C / Minute |

| Window Parameters 5 | |

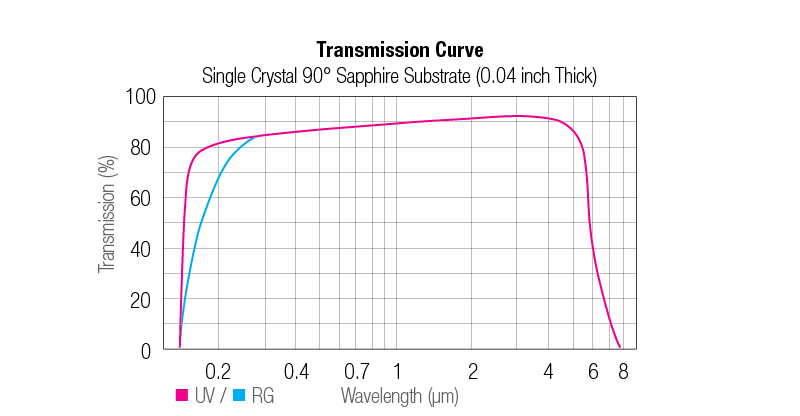

| Transmission (200-4000nm) | >80% |

| Surface Finish (Scratch-Dig) | 50-20 |

| Parallelism (Arc-Minutes) | <3 |

| TWD λ @ 632nm (Peak to Valley) | <8 |

| Notes |

- Since window material is inherently weak under point stresses, caution must always be exercised when handling viewports. The proper handling of viewports and components will greatly minimize the chance of implosion hazard and/or injury.

- Single Crystal, UV Grade Sapphire

- Leak tested to 5x10-10 Standard cc/sec of He.

- Overall assembly ratings must be adjusted to that of its lowest rated component. For cryogenic service, the lowest recommended temperature is -80°C

- Transmission curves are provided for reference only. Transmission for individual viewports may vary based on glass substrate thicknesses, surface finish and/or other conditions.

- Unless specified otherwise, website dimensional units are expressed in inches.