9-Pin HV Bulkhead-D Feedthrough Flange

9-Pin Subminiature-D on a 2x3.5 Inch HV Bulkhead-D Flange

9-Pin Subminiature-D on a 2x3.5 Inch HV Bulkhead-D Flange

15-Pin Subminiature-D on a 2x3.5 Inch HV Bulkhead-D Flange

25-Pin Subminiature-D on a 2x3.5 Inch HV Bulkhead-D Flange

50-Pin Subminiature-D on a 2x3.5 Inch HV Bulkhead-D Flange

Spare Gasket for 2x3.5 Inch HV Bulkhead-D Flanges

Spare Fastener Kit for 2x3.5 Inch HV Bulkhead-D Flanges

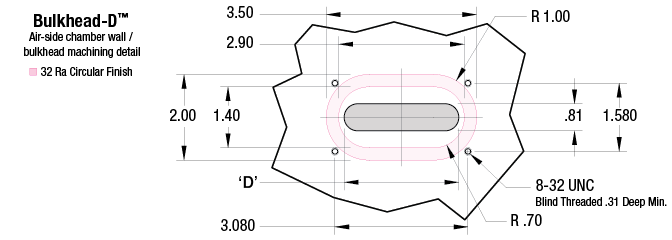

The HV (High Vacuum) Bulkhead-D feedthroughs were developed for high-vacuum flat-chamber-wall applications where conventional ISO NW KF or LF flanges are either not available, or just not practical. Our universal 2x3.5 inch rectangular flanges, the Bulkhead-D flange, accommodates standard 9, 15, 25 or 50-pin Subminiature-D feedthroughs, and shares the same gasket and fastening accessories... providing simple and convenient interchangeability.

Installation requires customer machining/polishing of chamber wall or bulkhead. See individual product drawings for instructions on how to prep your vacuum chamber for use with these HV Bulkhead-D feedthroughs.

| Electrical | |

| Voltage 1, Maximum | 500 VDC |

| Current 2, Maximum | 5 A |

| Material | |

| Shell, Stainless Steel Flange | 304 |

| Pins, Au plated | Ni-Fe |

| Seal / Insulator | Glass-Ceramic |

| Connector, Air | Composite |

| Connector, UHV 3 | PEEK |

| Connector, HV 3 | DAP / Stainless |

| Vacuum Range 4 | |

| HV, High vacuum | 1x10E-8 Torr |

| Temperature Range 5 | |

| Feedthrough | -200 to 250°C |

| Flange Seal, Viton® | 150°C |

| Connector / Cable, Air | 80°C |

| Connector / Cable, UHV PEEK | 250°C |

| Connector / Cable, HV, DAP | 125°C |

| Thermal Gradient, Maximum | 25°C/minute |

| Notes |