3 Pin Power Feedthrough on a KF50 Flange

D-Type Feedthrough, Consisting of 3 Power Pins on a KF50 Flange.

D-Type Feedthrough, Consisting of 3 Power Pins on a KF50 Flange.

D-Type Feedthrough, Consisting of 5 Power Pins on a NW63 LF Flange.

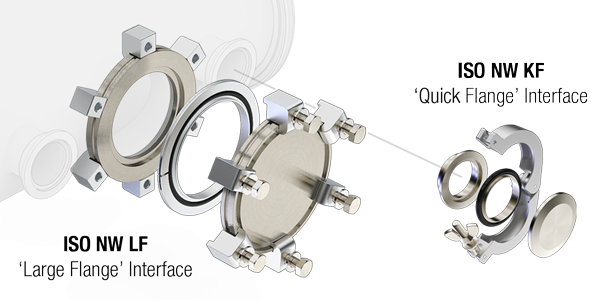

These Power-D ISO feedthroughs are mounted on ISO KF or LF Flanges that incorporate the industry standard "centering-ring O-ring" sealing principle, making it easy to mount to your existing KF/LF Flange ports. Accu-Glass Power-D™ — hermetic, high-current power feedthroughs, are designed to IEC 807-2 and DESC 85039 combination Subminiature-D interface specifications.

Three (3) and five (5) pin feedthroughs, with Au, plated Ni-Fe alloy pins, rated to 20 Amps per pin, are hermetically sealed and insulated into 304 stainless steel Subminiature-D shells using the latest in glass-ceramic / metal bonding technology. Mating cable assemblies with PEEK polymer connectors and Kapton® insulated leads are also available to meet the rigorous demands of UHV environments.

Vacuum and air-side cable assemblies, individual connectors, contacts, wiring tools, and other accessories can be found starting on page 40. Custom Power-D™ solutions are also available on request. Please contact the factory for more information.

| Electrical | |

| Voltage 1, Maximum | 500 VDC |

| Current, Maximum | 20 A |

| Material | |

| Shell, Stainless Steel | 304 |

| Pins, Au plated | Ni-Fe |

| Seal / Insulator | Glass-Ceramic |

| Connector, Air | Delrin® |

| Connector, UHV 2 | PEEK |

| Vacuum Range | |

| UHV, Ultrahigh vacuum | 1x10E-10 Torr |

| HV, High vacuum | 1x10E-8 Torr |

| Temperature Range 3 | |

| Feedthrough | 250°C |

| Flange, Conflat® | 450°C |

| Flange, ISO | 150°C |

| Connector / Cable, Air | 80°C |

| Connector / Cable, UHV PEEK | 250°C |

| Thermal Gradient, Maximum | 25°C/minute |

| Notes |