Demountable Substrate Viewports

Demountable Viewports

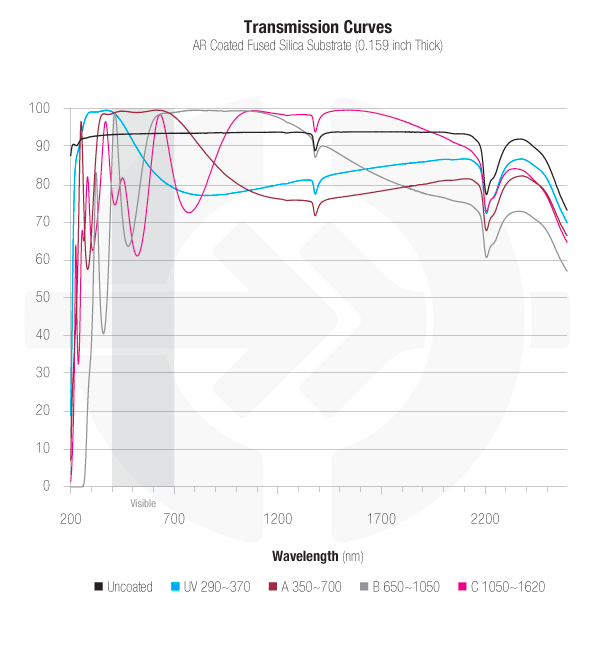

Accu-Glass Products' demountable substrate vacuum viewport flanges are an economical "alternative" to fused and/or brazed viewport solutions. They are available with Accu-Sol high-transmission glass or quartz (fused silica) substrate materials. Quartz versions are offered in coated and uncoated configurations. Substrate Transmission varies by material and/or coating option. Accu-Sol glass has greater than 90% transmission over the 350~2200nm spectral range. Quartz substrates are available with specially formulated broadband (BBAR) anti-reflection coatings for better than 99% transmission in the following discrete wavelength ranges... 290~370nm (UV), 350~700nm (A), 650~1050nm (B), 1050~1620nm (C). Uncoated quartz transmission varies from 70~95% over the 200~2200nm range.

The substrate removal (demountable) feature of these vacuum viewports allows optional (custom) optical coatings or for easy cleaning of the window substrate. For high-temperature applications up to 250°C, Kalrez® O-rings can be used. Accu-Glass demountable viewports employ a unique recessed zero profile substrate design, providing the widest viewing angles while offering maximum protection.

Accu-Glass' broadband anti-reflection coated viewports (BBAR) incorporate, precision ground, demountable UV grade fused silica windows that are ideal for use at high vacuum (HV) pressures. These viewports utilize Viton® O-ring elastomer seals to create an air-tight metal/glass seal suitable for pressures down to 10-8 Torr. Window substrates are interchangeable, allowing the user the ability to swap out vacuum windows mounted in our HV CF flanges should cleaning or an alternate AR coating be required.

Windows are available uncoated (185~2100 nm) or with one of four low-loss broadband anti-reflection coatings. Coatings are deposited on both optical surfaces and are optimized for the following ranges: UV (290~370 nm), A (350~700 nm), B (650~1050 nm), and C (1050~1620 nm). While uncoated windows have typical losses of about 4% per surface, the AR coatings reduce this to Ravg < 0.5%. We have designed these AR coatings for angles of incidence between 0° and 30°.