Fiber Optic Feedthroughs

UHV / HV Fiber Optic Feedthroughs and Cables

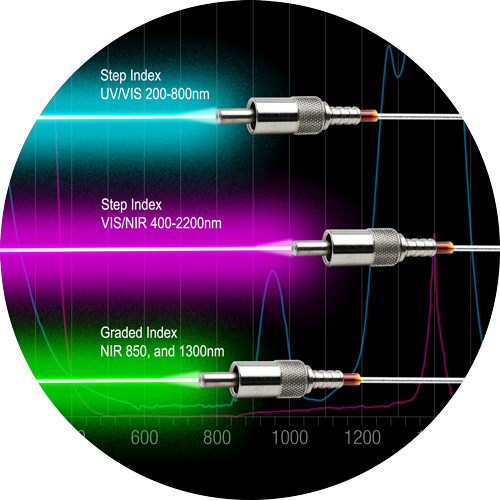

Fiber optic feedthroughs are constructed with 62.5, 100, 200, 400, 600, and 1000 micron UV/VIS or VIS/NIR, and NIR multimode fibers. These feedthroughs are ideally suited for industrial and/or scientific research applications requiring fiber optic connections from inside a vacuum system to external equipment. Multimode fibers (both Step and Graded Index types) are hermetically sealed into a stainless steel shell, using the latest in glass-ceramic bonding technology. Standard fiber optic feedthroughs are terminated with premium SMA 905 connectors on both the vacuum and air sides. FC and ST connections are also available.

Polyimide buffered fiber optic cable assemblies are offered to meet the rigorous demands of ultrahigh vacuum environments. These optical fibers are of a core-and-cladding composite construction. The core, or the filament that guides the light, consists of a thin strand of high-transmission fused silica. The cladding is an outer layer of doped, lower refractive-index fused silica. This dual-layer design tightly confines light to the fiber's central core, thus delivering the maximum amount of light possible at the fiber's destination. Fiber diameters are closely controlled during the drawing process, allowing fibers to center well in connectors and boast low loss rates.

All Accu-Glass Products' optical fibers are constructed as a core-and-cladding composite. The core, or the filament that guides the light, consists of a thin strand of high-transmission fused silica. The cladding consists of an outer layer of doped, lower-refractive-index fused silica. This two-layer design tightly confines the light to the central core of the fiber which in turn delivers a maximum amount of light at the far end. The fiber diameter is closely controlled during the drawing process. This allows the fiber to center well in connectors. A low loss rate is a result.

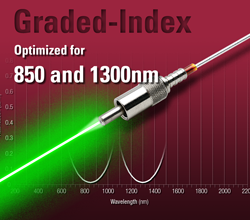

Graded-index multimode fiber bridges the gap between single mode and step-index multimode fibers, giving up some bandwidth for ease of termination and light launch. It's more economical than single mode fiber, and primarily used for data communication (not as useful for power transmission) applications requiring medium run distances (2 to 15 km lengths).

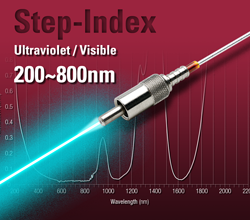

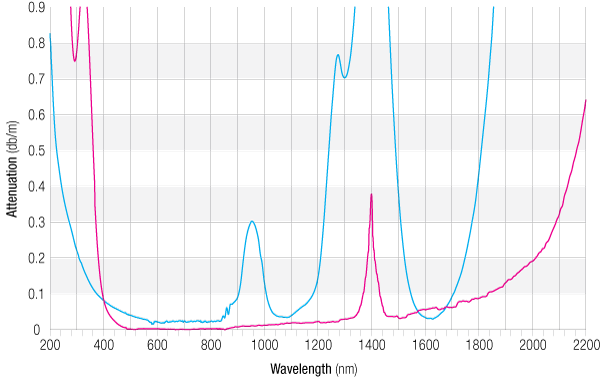

- █ High-OH, 200-800nm UV/VIS

For UV/VIS applications only. Use ≤ 15 meter lengths to avoid high attenuation.

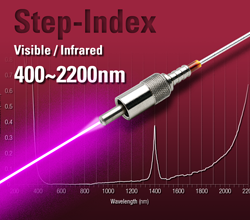

- █ Ultra Low-OH, 400–2200nm VIS/NIR

For extremely long length VIS/NIR applications. Lowest possible light attenuation.

Features

- UHV compatible construction

- 100, 200, 400, 600, and 1000μm

UV, VIS and NIR Step Index fibers - 62.5μm NIR Graded Index fiber

- SMA 905 premium connector interface

- High temperature rated to 250°C

- Conflat® and ISO KF compatible mounts

- Polyimide buffered vacuum rated optical cables

Specifications

| Material | |

| Hardware, Stainless Steel | 304 |

| Fiber Construction | |

| Core, Silica | SiO2 |

| Cladding, Fluorine-Doped Silica | F-SiO2 |

| Buffer, Aluminum (Feedthrough) | Al |

| Buffer, Polyimide (Cable) | PI |

| Vacuum Range | |

| UHV, Ultrahigh vacuum | 1x10E-10 Torr |

| HV, High vacuum | 1x10E-8 Torr |

| Temperature Range 1 | |

| Feedthrough | -200 to 250°C |

| Flange, Conflat® | -200 to 450°C |

| Flange, ISO | 150°C |

| Connector / Cable, Air | 80°C |

| Connector / Cable, UHV | -65 to 200°C |

| Thermal Gradient, Maximum | 25°C/minute |

| Step Index Fiber 2 | |

| Operational Wavelengths | |

| █ UV/VIS, High-OH | 200-800 nm |

| █ VIS/NIR, Ultra Low-OH | 400-2200 nm |

| Diameters, Five (5) Core | 100 to 1000 µm |

| Aperture, 24.8° Numerical | 0.22 ± 0.02 |

| Core / Cladding Ratio 3 | 1 : 1.1 |

| Power | < 1W |

| Bend Radius 4 | 200x |

| Momentary | 200x |

| Long Term | 400x |

| Insertion Loss 5, Interconnect | -0.8 to -2.0 dB |

| Graded Index Fiber | |

| Core Diameter | 62.5 µm |

| Clad Diameter | 125 µm |

| Operational Wavelengths 6, Two | |

| Optimized for use @ | 850 nm |

| Optimized for use @ | 1300 nm |

| Aperture, Numerical | 0.27 ± 0.02 |

| Bend Radius 4 | |

| Momentary | 400x |

| Long Term | 800x |

| Attenuation @ 850, and 1300 nm | |

| @ 850 nm | ≤ 3.0 dB |

| @ 1,300 nm | ≤ 0.8 dB |

| Notes |

- Overall assembly ratings must be adjusted to that of its lowest rated component. For cryogenic service, the lowest recommended temperature is -80°C

- Bare fiber has a pure fused-silica core, fluorine-doped silica cladding, and Polyimide buffer.

- Where core diameter is ≥ 200 µm

- Bend radius is expressed as this factor x the core diameter

- Dependent on wavelength and fiber size.

- Optimized for these two specific wavelengths